2021 China New Design Alloy 625 Flanges - 4J29-Kovar alloy strip Kovar bar/kovar sheet/kovar tube – Sekonic

2021 China New Design Alloy 625 Flanges - 4J29-Kovar alloy strip Kovar bar/kovar sheet/kovar tube – Sekonic Detail:

Common Trade Names:Kovar Alloy,4J29,UNS K94610(FeNi29Co17),29HК Kovar,KV-1,29HК-BИ,Werkstoff Nr.1.3981

This alloy also caleed Glass sealed and controlled expansion alloy,The alloy has a linear expansion coefficient similar to that of silicon boron hard glass at 20-450°C, a higher Curie point, and good low-temperature structural stability. The oxide film of the alloy is dense and can be well wetted by glass . It does not interact with mercury and is suitable for use in mercury-containing discharge meters. It is the main sealing structure material for electric vacuum devices.

Kovar Alloy Chemical Composition

| C | Cr | Ni | Mo | Si | Mn | P | S | Fe | Co | Cu |

| ≤0.03 | ≤0.2 | 28.5-29.5 | ≤0.2 | ≤0.3 | ≤0.5 | ≤0.02 | ≤0.02 | balance | 16.8-17.8 | ≤0.2 |

Kovar Physical properties

| Density(g/cm3) | Thermal conductivity(W/m·K) | Electrical resistivity(μΩ·cm) |

| 8.3 | 17 | 45 |

Kovar Average expansion coefficient

| Alloy Grades

|

The average linear expansion coefficient a,10-6/ oC | |||||||

| 20-200

oC |

20-300

oC |

20-400

oC |

20-450

oC |

20-500

oC |

20-600

oC |

20-700

oC |

20-800

oC |

|

| kovar | 5.9 | 5.3 | 5.1 | 5.3 | 6.2 | 7.8 | 9.2 | 10.2 |

Kovar average linear expansion coefficient in line

| Alloy Grades | Specimen heat treatment system | The average linear expansion coefficient α,10-6/ oC | ||

| Kovar | 20-300 oC | 20-400 oC | 20-450 oC | |

| In hydrogen atmosphere heated to 900 ± 20 oC, insulation 1h, and then heated to 1100 ± 20 oC, insulation 15min, to not more than 5 oC / min rate of cooling to below 200 oC released | —– | 4.6-5.2 | 5.1-5.5 | |

Kovar typical expansion coefficient

| Alloy Grades | The average linear expansion coefficient a,10-6/ oC | |||||||

| Kovar | 20-200oC | 20-300 oC | 20-400oC | 20-450oC | 20-500oC | 20-600oC | 20-700oC | 20-800oC |

| 5.9 | 5.3 | 5.1 | 5.3 | 6.2 | 7.8 | 9.2 | 10.2 | |

Kovar Alloy Available Products in Sekonic Metals

Kovar Bars & Rods

Round bars/Flat bars/Hex bars, Size From 8.0mm-320mm, Used for bolts,fastners and other spare parts

Kovar wire

Supply in welding wire and spring wire in coil form and cut length.

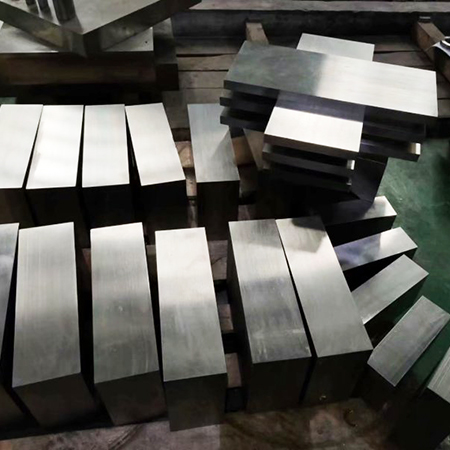

Kovar sheet & plate

Widths up to 1500mm and lengths up to 6000mm,Thickness from 0.1mm to 100mm.

Kovar seamless tube & Caplliary Tube

Standards size and customized dimension can be produced by us with small tolerance

Kovar strip & coil

Soft condition and hard condition with AB bright surface, width up to 1000mm

Why Inconel Kovar ?

1.Kovar has a wide usage in the electronics industry, such as metal parts bonded to hard glass envelopes. These parts are used for such devices as power tubes and X-ray tubes, etc.

2.In the semiconductor industry kovar is used in hermetically sealed packages for both integrated and discrete circuit devices.

3.Kovar is provided in a variety of forms to facilitate efficient manufacturing of various metal parts. It has thermal expansion characteristics matching those of hard glass. Used for matched expansion joints between metals and glass or ceramics.

4.Kovar alloy is a vacuum melted, iron-nickel-cobalt, low expansion alloy whose chemical composition is controlled within narrow limits to assure precise uniform thermal expansion properties. Extensive quality controls are employed in the manufacture of this alloy to ensure uniform physical and mechanical properties for ease in deep drawing, stamping and machining.

Kovar Alloy Application field:

● Kovar alloy has been used for making hermetic seals with the harder Pyrex glasses and ceramic materials.

●This alloy has found wide application in power tubes, microwave tubes, transistors and diodes. In intergrated circuits, it has been used for the flat pack and the dual-in-line package.

Product detail pictures:

Related Product Guide:

Special Materials we offer

electropolished

Our advantages are lessen charges,dynamic income team,specialized QC,sturdy factories,premium quality services for 2021 China New Design Alloy 625 Flanges - 4J29-Kovar alloy strip Kovar bar/kovar sheet/kovar tube – Sekonic , The product will supply to all over the world, such as: America, Canada, Liverpool, We hope we can establish long-term cooperation with all of the customers. And hope we can improve competitiveness and achieve the win-win situation together with the customers. We sincerely welcome the customers from all over the world to contact us for anything you need!

After the signing of the contract, we received satisfactory goods in a short term, this is a commendable manufacturer.