2021 China New Design Nickel Alloy Tube - Hastelloy C-4 BAR/ SHEET/ BOLT/ Pipe – Sekonic

2021 China New Design Nickel Alloy Tube - Hastelloy C-4 BAR/ SHEET/ BOLT/ Pipe – Sekonic Detail:

Common Trade Names: Hastelloy C-4 , Alloy C4, NS3305, UNS N06455 , W.Nr.2.4610

Hastelloyc C-4 is an austenitic low carbon nickel-molybdenum chromium alloy.

The main difference between HastelloyC-4 and other early developed alloys of similar chemical composition is the low carbon, ferrosilicate, and tungsten content.

Such chemical composition makes it show excellent stability at 650-1040℃, improve the ability to resist intergranular corrosion, under appropriate manufacturing conditions can avoid edge line corrosion sensitivity and weld heat affected zone corrosion.

Hastelloy C-4 Chemical Composition

| Alloy |

% |

Fe |

Cr |

Ni |

Mo |

Co |

C |

Mn |

Si |

S |

P |

W |

V |

|

Hastelloy C-4 |

Min. |

- |

14.0 |

balance |

14.0 | - | - | - | - | - | - |

2.5 |

- |

|

Max. |

3.0 |

18.0 |

17.0 |

2.0 | 0.015 | 3.0 | 0.1 | 0.01 | 0.03 | 3.5 | 0.2 |

Hastelloy C-4 Physical Properties

| Density | 8.94 g/cm³ |

| Melting point | 1325-1370 ℃ |

Hastelloy C-4 Mechanical Properties

| Status |

Tensile strength Rm N/mm² |

Yield strength Rp 0. 2N/mm² |

Elongation As % |

Brinell hardness HB |

| Solution treatment | 690 | 276 | 40 | - |

Hastelloy C-4 Standards and Specifications

| Bar/Rod | Strip/Coil | Sheet/Plate | Pipe/Tube | Forgings |

| ASTM B335 | ASTM B333 | ASTM B622,ASTM B619,ASTM B626 | ASTM B564 | |

Hastelloy C-4 Available Products in Sekonic Metals

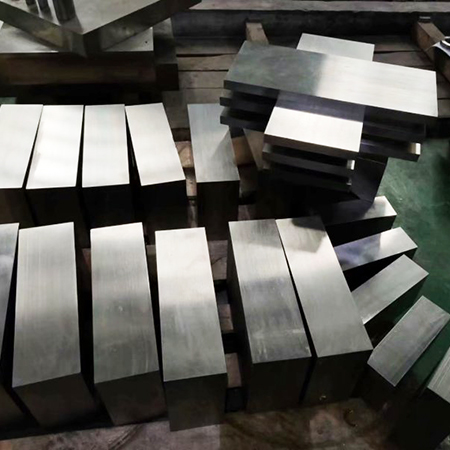

Hastelloy C-4 bars & Rods

Round bars/Flat bars/Hex bars, Size From 8.0mm-320mm, Used for bolts,fastners and other spare parts

Hastelloy C-4 Forging Ring

Forging Ring or gasket,size can be customized with bright surface and precision tolerance

Hastelloy C-4 sheet & plate

Widths up to 1500mm and lengths up to 6000mm,Thickness from 0.1mm to 100mm.

Hastelloy C-4 seamless tube & Welded pipe

Standards size and customized dimension can be produced by us with small tolerance

Hastelloy C-4 strip & coil

Soft condition and hard condition with AB bright surface, width up to 1000mm

Hastelloy C-4 Fasetners

Hastelloy C-4 materials in forms of Bolts,screws,flanges and other fasterners, according to clients specification.

Why Hastelloy C-4 ?

• Excellent corrosion resistance to most corrosive media, especially in reduced condition.

• Excellent local corrosion resistance in halides.

Hastelloy C-4 Application field:

• Flue gas desulfurization system

• Pickling and acid regeneration plants

• Acetic acid and agro-chemical production

• Titanium dioxide production (chlorine method)

• Electroplating

Product detail pictures:

Related Product Guide:

Why Cobalt based Alloys

Why Nickel Based Alloys ?

We also offer you product sourcing and flight consolidation expert services. We've our personal manufacturing unit and sourcing business. We can offer you virtually every variety of merchandise associated to our item range for 2021 China New Design Nickel Alloy Tube - Hastelloy C-4 BAR/ SHEET/ BOLT/ Pipe – Sekonic , The product will supply to all over the world, such as: Maldives, Philippines, Senegal, Our company abides by the management idea of "keep innovation, pursue excellence". On the basis of assuring the advantages of existing merchandise, we continuously strengthen and extend product development. Our company insists on innovation to promote the sustainable development of enterprise, and make us become the domestic high-quality suppliers.

Cooperate with you every time is very successful, very happy. Hope that we can have more cooperation!