2021 Good Quality Nickel Wire - Inconel 713LC round bar – Sekonic

2021 Good Quality Nickel Wire - Inconel 713LC round bar – Sekonic Detail:

Common Trade Names: 713LC,Inconel 713LC

Inconel 713 lc is isometric nickel-based precipitation hardening type casting high temperature alloy, is the modification alloy Inconel 713 c, the use of temperature under 900 compared with Inconel 713 c alloy, reduce the carbon content of adjusting the content of chromium and molybdenum alloy has good resistance to creep rupture and cold and hot fatigue resistance, and significantly improve the room temperature plasticity, impact performance and stable organization performance This is of good performance in the application of integral casting turbine has great superiority

In addition, the alloy is not sensitive to the section size and cooling rate of the casting, so it is suitable for casting large castings with a section of more than 130mm

Inconel 713LC Chemical Composition

| Alloy |

% |

Fe |

Cr |

Ni |

Mo |

Nb |

Co |

C |

Mn |

Si |

S |

Cu |

Al |

Ti |

P |

B |

Zr |

|

713LC |

Min. |

|

11.0 |

balance |

3.8 |

1.5 | - | 0.03 | - | - | - | - | 5.5 |

0.4 |

- |

0.005 |

0.05 |

|

Max. |

0.5 |

13.0 |

5.2 |

2.5 | 1.0 | 0.07 | 0.25 | 0.5 | 0.015 | 0.5 | 6.5 | 1.0 | 0.015 | 0.015 | 0.15 |

Inconel 713LC Physical Properties

| Density | 8.01 g/cm³ |

| Melting point | 1288-1321 ℃ |

Inconel 713LC Mechanical Properties In The Roomtemperature

| Status |

Tensile strength Rm N/mm² |

Yield strength Rp 0. 2N/mm² |

Elongation As % |

| Solution treatment | - | 760 | 9.5 |

Inconel 713LC Available Products in Sekonic Metals

Inconel 713LC bars & Rods

Round bars/Flat bars/Hex bars, Size From 8.0mm-320mm, Used for bolts,fastners and other spare parts

Inconel 713LC sheet & plate

Widths up to 1500mm and lengths up to 6000mm,Thickness from 0.1mm to 100mm.

Inconel 713LC Forging Ring

Forging Ring or gasket,size can be customized with bright surface and precision tolerance

Inconel 713LC welding performance:

Electron beam welding, argon arc welding, isothermal solidification diffusion welding and friction welding can be performed.

Inconel 713LC Application field:

Alloy was used in aeroengine freedom of turbine rotor blade turbine guide and the whole rotor parts such as close to the alloy of 713 lc has been widely used, including production of aeroengine turbine guide the whole rotor blade, unmanned aircraft engine turbine disc, and production for long time use of integral casting turbine power generation with gas turbine, etc

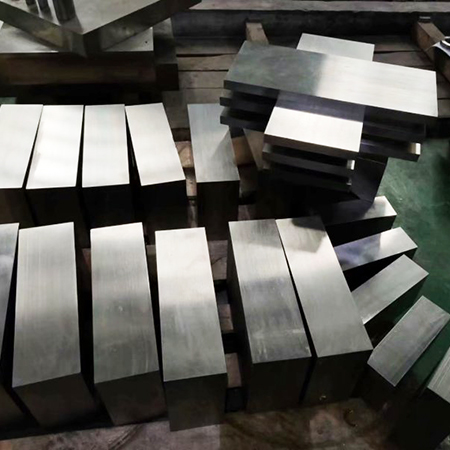

Product detail pictures:

Related Product Guide:

Special Materials we offer

Why Nickel Based Alloys ?

As for competitive selling prices, we believe that you will be searching far and wide for anything that can beat us. We will state with absolute certainty that for such excellent at such charges we are the lowest around for 2021 Good Quality Nickel Wire - Inconel 713LC round bar – Sekonic , The product will supply to all over the world, such as: Anguilla, Singapore, Mali, With the spirit of "credit first, development through innovation, sincere cooperation and joint growth", our company is striving to create a brilliant future with you, so as to become a most valuable platform for exporting our goods in China!

With a positive attitude of "regard the market, regard the custom, regard the science", the company works actively to do research and development. Hope we have a future business relationships and achieving mutual success.