Bottom price Inconel Sheet - Stainless steel 17-7PH – Sekonic

Bottom price Inconel Sheet - Stainless steel 17-7PH – Sekonic Detail:

Common Trade Names: 17-7PH,SUS631,S17700,07Cr17Ni7Al,W.Nr.1.4568

17-7PH is austenitic-martensitic precipitation hardening stainless steel developed on the basis of 18-8CrNi, also known as controlled phase change stainless steel.At the solution treating temperature, 1900°F, the metal is austenitic but undergoes transformation to a low-carbon martensitic structure during cooling to room temperature. This transformation is not complete until the temperature drops to 90°F. Subsequent heating to temperatures of 900-1150°F for one to four hours precipitation strengthens the alloy. This hardening treatment also tempers the martensitic structure, increasing ductility and toughness

17-7PH Chemical Composition

| C | Cr | Ni | Si | Mn | P | S | Al |

| ≤0.09 | 16.0-18.0 | 6.5-7.75 | ≤1.0 | ≤1.0 | ≤0.04 | ≤0.03 | 0.75-1.5 |

17-7PH Physical Properties

| Density (g/cm3) | Melting point(℃) |

| 7.65 | 1415-1450 |

17-7PH Mechanical Properties

| Condition | бb/N/mm2 | б0.2/N/mm2 | δ5/% | ψ | HRW | |

| Solution treatment | ≤1030 | ≤380 | 20 | - | ≤229 | |

| Precipitationhardening | 510℃ageing | 1230 | 1030 | 4 | 10 | ≥383 |

| 565℃ageing | 1140 | 960 | 5 | 25 | ≥363 | |

17-7PH Standards and Specifications

AMS 5604, AMS 5643, AMS 5825,ASME SA 564, ASME SA 693, ASME SA 705, ASME Type 630,ASTM A 564, ASTM A 693, ASTM A 705, ASTM Type 630

Condition A – H1150,ISO 15156-3,NACE MR0175,S17400,UNS S17400,W. Nr./EN 1.4548

| Bar/Rod | Wire | Strip/Coil | Sheet/Plate | Pipe/Tube |

17-7PH Available Products in Sekonic Metals

17-7PH Bars & Rods

Round bars/Flat bars/Hex bars, Size From 8.0mm-320mm, Used for bolts,fastners and other spare parts

17-7PH Wire

Supply in welding wire and spring wire in coil form and cut length.

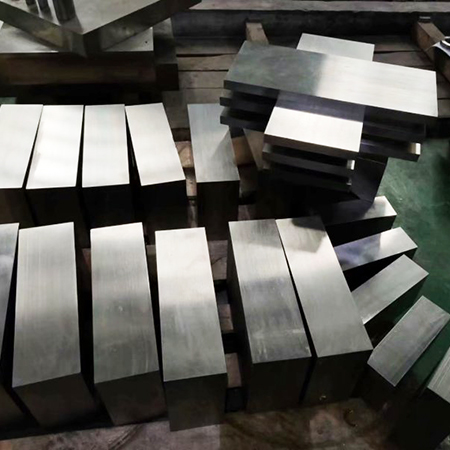

17-7PH sheet & plate

Widths up to 1500mm and lengths up to 6000mm,Thickness from 0.1mm to 100mm.

17-7PH seamless tube & Welded pipe

Standards size and customized dimension can be produced by us with small tolerance

17-7PH strip & coil

Soft condition and hard condition with AB bright surface, width up to 1000mm

17-7PH Fasteners

17-7PH materials in forms of Bolts,screws,flanges and other fasterners, according to clients specification.

Why 17-7 PH?

• High tensile strength and hardness to 600°F

• Corrosion resistant

• Excellent oxidation resistance to about 1100°F

• Creep-rupture strength to 900°F

17-7 PHApplication field:

• Gate valves

• Chemical processing equipment

• Pump shafts, gears, plungers

• Valve stems, balls, bushings, seats

• Fasteners

Product detail pictures:

Related Product Guide:

Why Nickel Based Alloys ?

electropolished

"Quality initial, Honesty as base, Sincere support and mutual profit" is our idea, so as to build repeatedly and pursue the excellence for Bottom price Inconel Sheet - Stainless steel 17-7PH – Sekonic , The product will supply to all over the world, such as: Moldova, Turkmenistan, Swedish, In order to meet more market demands and long-term development, a 150, 000-square-meter new factory is under construction, which will be put into use in 2014. Then, we shall own a large capacity of producing. Of course, we will continue improving the service system to meet the requirements of customers, bringing health, happiness and beauty to everyone.

The company keeps to the operation concept "scientific management, high quality and efficiency primacy, customer supreme", we have always maintained business cooperation. Work with you,we feel easy!