Chinese Professional Nickel Welding Wire - Inconel 617 bar /wire /Plate/ Pipe /Ring – Sekonic

Chinese Professional Nickel Welding Wire - Inconel 617 bar /wire /Plate/ Pipe /Ring – Sekonic Detail:

Common Trade Names: Inconel 617, Alloy 617, Nicrofer 617,UNS N06617,W.Nr. 2.4663

Alloy 617 is a solid-solution, nickel-chromium-cobalt-molydenum alloy with an exceptional combination of high-temperature strength and oxidation resistance. The alloy also has excellent resistance to a wide range of corrosive environment, and it is readily formed and welded by conventional techniques. The high nickel and chromium contents make the alloy resistant to a variety of both reducing and oxidizing media. The aluminum, in conjunction with the chromium, provides oxidation resistance at high temperatures. Solid-solution strengthening is imparted by the cobalt and molydenum.

Inconel 617 Chemical Composition

| Alloy |

% |

Fe |

Cr |

Ni |

Mo |

P |

Co |

C |

Mn |

Si |

S |

Cu |

Al |

Ti |

B |

|

617 |

Min. |

|

20.0 |

Remainder |

8.0 | 10.0 | 0.05 |

0.8 |

|

||||||

|

Max. |

3.0 |

24.0 |

10.0 |

0.015 | 15.0 | 0.15 | 0.5 | 0.5 | 0.015 | 0.5 |

1.5 |

0.6 | 0.006 |

Inconel 617 Physical Properties

| Density | 8.36 g/cm³ |

| Melting point | 1332-1380 ℃ |

Inconel 617 Typical Mechanical Properties

|

Product |

Production |

Yield Strength (0.2% Offset) |

Tensile Strength |

Elongation, |

Reduction |

Hardness |

||

|

1000 psi |

MPa |

1000 psi |

MPa |

|||||

|

Plate |

Hot Rolling |

46.7 |

322 |

106.5 |

734 |

62 |

56 |

172

|

Inconel 617 Standards and Specifications

| Bar/Rod | Wire | Strip/Coil | Sheet/Plate | Pipe/Tube | Forgings |

| ASTM B 166; AMS 5887,DIN 17752 , VdTÜV485 | ASTM B 166; ISO 9724 ,DIN 17753 | ASME SB 168,AMS 5889,ISO 6208,DIN 17750, VdTÜV 485 | ASME SB 168,AMS 5888,AMS 5889,ISO 6208,DIN 17750 | ASTM B 546; ASME SB 546,DIN 17751,VdTÜV 485 | ASTM B 564 AMS 5887, |

Inconel 617 Available Products in Sekonic Metals

Inconel 617 bars & Rods

Round bars/Flat bars/Hex bars, Size From 8.0mm-320mm, Used for bolts,fastners and other spare parts

Inconel 617 welding wire & Spring wire

Supply in welding wire and spring wire in coil form and cut length.

Inconel 617 sheet & plate

Widths up to 1500mm and lengths up to 6000mm,Thickness from 0.1mm to 100mm.

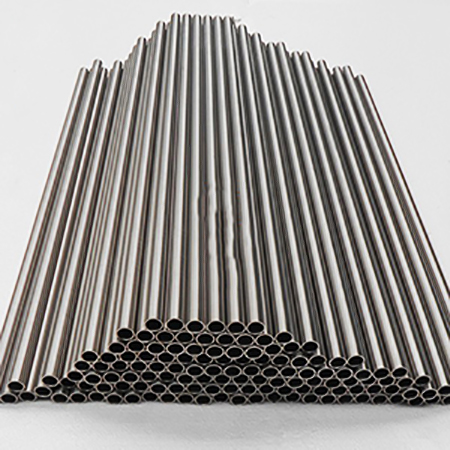

Inconel 617 seamless tube & Welded pipe

Standards size and customized dimension can be produced by us with small tolerance

Inconel 617 strip & coil

Soft condition and hard condition with AB bright surface, width up to 1000mm

Inconel 617 Forging Ring

Forging Ring or gasket,size can be customized with bright surface and precision tolerance

Why Inconel 617 ?

Alloy in the field of hot corrosion environment such as sulfide, especially in the environment up to 1100 ℃ circulating oxidation and carbonization, has excellent corrosion resistance.The corrosion resistance combined with excellent mechanical properties, makes it particularly suitable for high temperature field. good transient and long term mechanical properties until the 1100 °C.

Inconel 617 Application field:

The combination of high strength and oxidation resistance at temperatures over 1800°F makes alloy 617 an attractive material for such components as ducting, combustion cans, and transition liner in both aircraft, and land based gas turbines. Because of its resistance to high-temperature corrosion, the alloy is used for catalyst-grid supports in the production of nitric acid, for heat-treating baskets, and for reduction boats in the refining of molybdenum. Alloy 617 also offers attractive properties for components of power-generating plants, both fossil-fueled and nuclear.

• Gas turbines for combustion cans • Dducting

• Transition liners • Petrochemical processing

• heat-treating equipment • Nitric acid production

• Oil Power Plants • Nuclear Power Plants

• Components of power-generating plants

Product detail pictures:

Related Product Guide:

Why Cobalt based Alloys

electropolished

Assume full obligation to meet all demands of our customers; accomplish ongoing advancements by promoting the advancement of our customers; become the final permanent cooperative partner of clientele and maximize the interests of shoppers for Chinese Professional Nickel Welding Wire - Inconel 617 bar /wire /Plate/ Pipe /Ring – Sekonic , The product will supply to all over the world, such as: Melbourne, Florida, Turin, With the development of the society and economy, our company will continue the "loyalty, dedication, efficiency, innovation" spirit of enterprise, and we will always adhere to the management idea of "would rather lose gold, do not lose customers heart". We will serve the domestic and foreign businessmen with sincere dedication, and let us create bright future together with you!

This company conforms to the market requirement and joins in the market competition by its high quality product, this is an enterprise that have Chinese spirit.