Good Wholesale Vendors Alloy 718 Round Bar - Alloy N155 (R30155) Sheet, Plate – Sekonic

Good Wholesale Vendors Alloy 718 Round Bar - Alloy N155 (R30155) Sheet, Plate – Sekonic Detail:

Common Trade Names: Alloy N155, Multimet N155, R30155 , W.Nr 1.4974

Alloy N155 is a Nickel-Chromium-Cobalt alloy with additions of Molybdenum and Tungsten used typically in parts requiring high strength up to 1350°F and oxidation resistance up to 1800°F. Its high-temperature properties are inherent in the as-supplied condition (solution treated at 2150°F) and are not dependent on age-hardening. Multimet N155 is used in a number of aerospace applications such as tailpipes and tail cones, turbine blades, shafts and rotors, afterburner components and high-temperature bolts.

Alloy N155 Chemical Composition

| Alloy |

% |

C |

Si |

Fe |

Mn |

P |

S |

Cr |

Ni |

Co |

Mo |

W |

Nb |

Cu |

N |

|

N155 |

Min. |

0.08 |

bal |

1.0 |

20.0 | 19.0 | 18.5 | 2.5 | 2.0 | 0.75 |

0.1 |

||||

|

Max. |

0.16 |

1.0 |

2.0 |

0.04 |

0.03 |

22.5 |

21.0 |

21.0 |

3.5 |

3.0 |

1.25 |

0.5 |

0.2 |

Alloy N155 Physical Properties

| Density | 8.25 g/cm³ |

| Melting point | 2450 ℃ |

Alloy N155 Mechanical Properties

| Status | Tensile strength Rm N/mm² |

Yield strength Rp 0. 2N/mm² |

Elongation As % |

Brinell hardness HB |

| Solution treatment | 690-965 | 345 | 20 | 82-92 |

Alloy N155 Standards and Specifications

AMS 5532 ,AMS 5769 ,AMS 5794,AMS 5795

| Bar/Rod Forging |

Wire | Strip/Coil | Sheet/Plate |

| AMS 5769 | AMS 5794 | AMS 5532 | AMS 5532 |

Alloy N155 Available Products in Sekonic Metals

Alloy N155 bars & Rods

Round bars/Flat bars/Hex bars, Size From 8.0mm-320mm, Used for bolts,fastners and other spare parts

Alloy N155 welding wire & Spring wire

Supply in welding wire and spring wire in coil form and cut length.

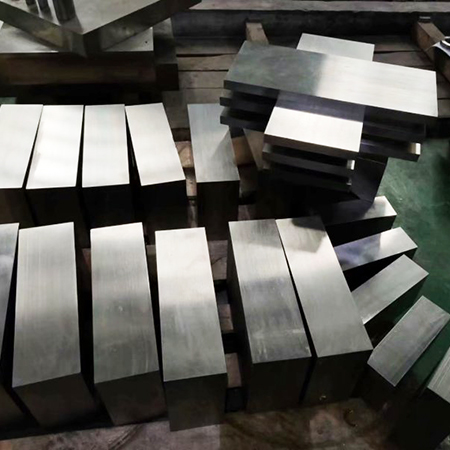

Alloy N155 sheet & plate

Widths up to 1500mm and lengths up to 6000mm,Thickness from 0.1mm to 100mm.

Alloy N155 Forging Ring

Forging Ring or gasket,size can be customized with bright surface and precision tolerance

Alloy N155 strip & coil

Soft condition and hard condition with AB bright surface, width up to 1000mm

Why Alloy N155?

Alloy N155 has good resistance to corrosion in certain media under both oxidizing and reducing conditions. When solution heat treated, alloy N155 alloy has about the same resistance to nitric acid as does stainless steel. It has better resistance than stainless steel to weak solutions of hydrochloric acid. It withstands all concentrations of sulfuric acid at room temperature. The alloy can be machined, forged and cold-formed by conventional methods.

The alloy can be welded by various arc and resistance-welding processes. This alloy is available as sheet, strip, plate, wire, coated electrodes, billet stock and sane and investment castings.

It is also available in the form of re-melt stock to a certified chemistry. Most wrought forms of n155 alloy are shipped in the solution heat-treated condition to assure optimum properties. Sheet is given a solution heat-treatment of 2150°F, for a time dependent upon section thickness, followed by a rapid air cool or water quench. Bar stock and plate (1/4 in. and heavier) are usually solution heat treated at 2150°F followed by water quench.

Alloy N155 suffered from mediocre oxidation resistance, a tendency for heat affected zone cracking during welding, and a relatively wide scatter band of mechanical properties

Product detail pictures:

Related Product Guide:

Why Cobalt based Alloys

electropolished

We not only will try our greatest to offer superb companies to just about every buyer, but also are ready to receive any suggestion offered by our shoppers for Good Wholesale Vendors Alloy 718 Round Bar - Alloy N155 (R30155) Sheet, Plate – Sekonic , The product will supply to all over the world, such as: Croatia, Latvia, Zambia, We are your reliable partner in international markets with the best quality products. Our advantages are innovation, flexibility and reliability which have been built during the last twenty years. We focus on providing service for our clients as a key element in strengthening our long-term relationships. Our continual availability of high grade products in combination with our excellent pre-sales and after-sales service ensures strong competitiveness in an increasingly globalized market.

Speaking of this cooperation with the Chinese manufacturer, I just want to say"well dodne", we are very satisfied.