High definition Nimonic Alloy - Alloy Refractaloy 26/ R26 Turbine Bolt used in steam turbine and generating machinery – Sekonic

High definition Nimonic Alloy - Alloy Refractaloy 26/ R26 Turbine Bolt used in steam turbine and generating machinery – Sekonic Detail:

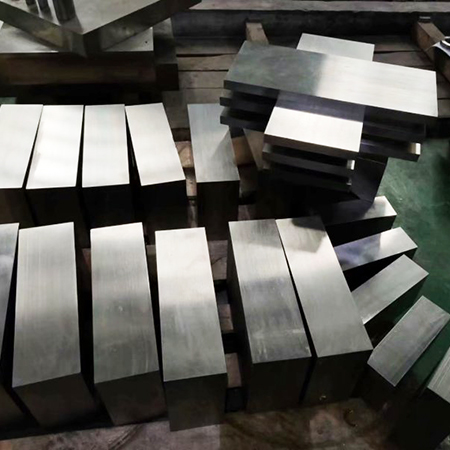

Alloy R26 bolt, Stud bolt, double bolt, Hexagon bolt

♦ Thread Size: M10-M120

♦ Length: according to clients drawing or specifaction

♦ Application for : Steam turbine generating equipment

♦ Grade: A Class

Refractaloy 26 is Fe – NI – Co – Cr precipitation hardening type deformation of high temperature alloy, long-term use of C – 570 ℃ temperature range of 540 ℃, the highest temperature can reach 677 C, add element of a Cr, mo alloy solid solution strengthening, high to low titanium, aluminum form y aging strengthening phase, while drilling elements made of titanium, aluminum solubility in the solid solution is reduced, prompted y phase precipitation amount increase, so as to improve the thermal stability of y, reduce y ‘phase of the stacking fault energy.

The composite properties of the alloy are superior, with excellent tensile resistance, force relaxation and creep resistance, no notch sensitivity.

Refractaloy 26 Chemical Composition

| Alloy |

% |

Ni |

Cr |

Fe |

Mo |

P |

Co |

C |

Mn |

Si |

S |

B |

Al |

Ti |

|

Refractaloy 26 |

Min. |

35.0 |

16.0 |

bal |

2.5 |

- | 18.0 | - | - | - | - | 0.001 | - | 2.5 |

|

Max. |

39.0 | 20.0 | 3.5 | 0.03 | 22.0 | 0.08 | 1.0 | 1.5 | 0.03 | 0.01 | 0.25 | 3.0 |

Refractaloy 26 Physical Properties

| Density | 8.2 g/cm³ |

| Melting point | 1200 ℃ |

Refractaloy 26 Mechanical Properties

| Status |

Tensile strength Rm N/mm² |

Yield strength Rp 0. 2N/mm² |

Elongation As % |

Brinell hardness HB |

| Solution +Aging | 1000 | 550 | 20 |

331-262 (26-35.5) |

Product detail pictures:

Related Product Guide:

Why Cobalt based Alloys

electropolished

We constantly continually give you essentially the most conscientious client provider, plus the widest variety of designs and styles with finest materials. These initiatives include the availability of customized designs with speed and dispatch for High definition Nimonic Alloy - Alloy Refractaloy 26/ R26 Turbine Bolt used in steam turbine and generating machinery – Sekonic , The product will supply to all over the world, such as: Paris, Uruguay, Norway, With all these supports, we can serve every customer with quality product and timely shipping with highly responsibility. Being a young growing company, we might not the best, but we're trying our best to be your good partner.

This manufacturers not only respected our choice and requirements, but also gave us a lot of good suggestions, ultimately, we successfully completed the procurement tasks.