Hot New Products Alloy C276 Flanges - Titanium Bar – Sekonic

Hot New Products Alloy C276 Flanges - Titanium Bar – Sekonic Detail:

Titanium bar and Titanium Rod can be used in the drawing parts for its good elongation and excellent corrosion-resistance and most widely applied in pressure,vessel and used in some fittings parts and fastening pieces, like titanium fasteners. Titanium bar and titanium rod also can be widely used in the titanium alloys because of its comprehensive mechanical and chemical properties. In addition, titanium bar and titanium rod can be used in the golf clubs and bicycle girders and medical appliance.

Two types of Titanium rods are available: pure Titanium rods and Titanium alloy rods such as Ti-6AI-4V. They can be used in aircraft engines and parts, chemical equipment parts (reactors, pipes, heat exchangers and valves, etc.), ship hulls, bridges, medical implants, artificial bones, sporting products and consumer goods.

• Tittanium Bar Materials: Grade1, Grade 2, Grade 5, Grade 5, Grade7 ,Grade9,Grade11, Grade12, Grade 16, Grade23 ect

• Bar Shapes: Round Bar, Flat Bar, Hex Bar, Square bar

• Diameter:2.0mm-320mm, Length: 50mm-6000mm, Customized

• Conditions: Hot Forging & Hot Rolling,Cold Rolled, Annealed

• Standards: ASTMB348, AMS4928, AMS 4931B, ASTM F67, ASTM F136 etc

| Titanium Alloys Material Common Name | ||

|

Gr1 |

UNS R50250 |

CP-Ti |

|

Gr2 |

UNS R50400 |

CP-Ti |

|

Gr4 |

UNS R50700 |

CP-Ti |

|

Gr7 |

UNS R52400 |

Ti-0.20Pd |

|

G9 |

UNS R56320 |

Ti-3AL-2.5V |

|

G11 |

UNS R52250 |

Ti-0.15Pd |

|

G12 |

UNS R53400 | Ti-0.3Mo-0.8Ni |

|

G16 |

UNS R52402 | Ti-0.05Pd |

|

G23 |

UNS R56407 |

Ti-6Al-4V ELI |

♦ Titanium Bar Chemical Composition ♦

|

Grade |

Chemical composition, weight percent (%) |

||||||||||||

|

C (≤) |

O (≤) |

N (≤) |

H (≤) |

Fe (≤) |

Al |

V |

Pd |

Ru |

Ni |

Mo |

Other Elements Max. each |

Other Elements Max. total |

|

|

Gr1 |

0.08 |

0.18 |

0.03 |

0.015 |

0.20 |

— |

— |

— |

— |

— |

— |

0.1 |

0.4 |

|

Gr2 |

0.08 |

0.25 |

0.03 |

0.015 |

0.30 |

— |

— |

— |

— |

— |

— |

0.1 |

0.4 |

|

Gr4 |

0.08 |

0.25 |

0.03 |

0.015 |

0.30 |

— |

— |

— |

— |

— |

— |

0.1 |

0.4 |

|

Gr5 |

0.08 |

0.20 |

0.05 |

0.015 |

0.40 |

5.5 6.75 |

3.5 4.5 |

— |

— |

— |

— |

0.1 |

0.4 |

|

Gr7 |

0.08 |

0.25 |

0.03 |

0.015 |

0.30 |

— |

— |

0.12 0.25 |

— |

0.12 0.25 |

— |

0.1 |

0.4 |

|

Gr9 |

0.08 |

0.15 |

0.03 |

0.015 |

0.25 |

2.5 3.5 |

2.0 3.0 |

— |

— |

— |

— |

0.1 |

0.4 |

|

Gr11 |

0.08 |

0.18 |

0.03 |

0.15 |

0.2 |

— |

— |

0.12 0.25 |

— |

— |

— |

0.1 |

0.4 |

|

Gr12 |

0.08 |

0.25 |

0.03 |

0.15 |

0.3 |

— |

— |

— |

— |

0.6 0.9 |

0.2 0.4 |

0.1 |

0.4 |

|

Gr16 |

0.08 |

0.25 |

0.03 |

0.15 |

0.3 |

— |

— |

0.04 0.08 |

— |

— |

— |

0.1 |

0.4 |

|

Gr23 |

0.08 |

0.13 |

0.03 |

0.125 |

0.25 |

5.5 6.5 |

3.5 4.5 |

— |

— |

— |

— |

0.1 |

0.1 |

♦ Titanum Alloy Bars Physical Properties ♦

|

Grade |

Physical properties |

|||||

|

Tensile strength Min |

Yield strength Min (0.2%,offset) |

Elongation in 4D Min (%) |

Reduction of Area Min (%) |

|||

|

ksi |

MPa |

ksi |

MPa |

|||

|

Gr1 |

35 |

240 |

20 |

138 |

24 |

30 |

|

Gr2 |

50 |

345 |

40 |

275 |

20 |

30 |

|

Gr4 |

80 |

550 |

70 |

483 |

15 |

25 |

|

Gr5 |

130 |

895 |

120 |

828 |

10 |

25 |

|

Gr7 |

50 |

345 |

40 |

275 |

20 |

30 |

|

Gr9 |

90 |

620 |

70 |

483 |

15 |

25 |

|

Gr11 |

35 |

240 |

20 |

138 |

24 |

30 |

|

Gr12 |

70 |

483 |

50 |

345 |

18 |

25 |

|

Gr16 |

50 |

345 |

40 |

275 |

20 |

30 |

|

Gr23 |

120 |

828 |

110 |

759 |

10 |

15 |

♦ ♦ ♦ Titanium Alloy Materials Features: ♦ ♦ ♦

• Grade 1: Pure Titanium, relatively low strength and high ductility.

• Grade 2: The pure titanium most used. The best combination of strength

• Grade 3: High strength Titanium, used for Matrix-plates in shell and tube heat exchangers

• Grade 5: The most manufactured titanium alloy. Exceedingly high strength. high heat resistance.

• Grade 7: Superior corrosion resistance in reducing and oxidizing environments.

• Grade 9: Very high strength and corrosion resistance.

• Grade 12: Better heat resistance than pure Titanium. Applications as for Grade 7 and Grade 11.

• Grade 23: Titanium-6Aluminum-4Vanadium ELI (Extra Low Interstitial) Alloy for surgical implant application.

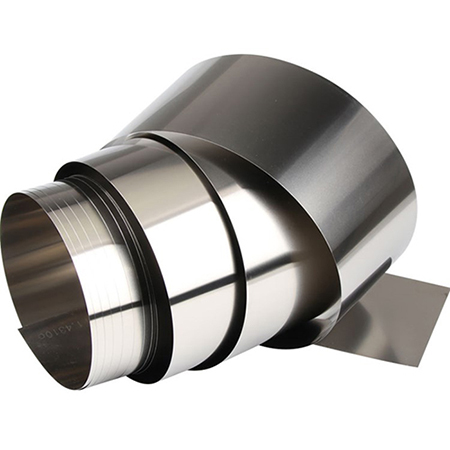

Product detail pictures:

Related Product Guide:

Special Materials we offer

Why Cobalt based Alloys

We thinks what clients think, the urgency of urgency to act from the interests of a client position of theory, allowing for greater quality, lessen processing costs, price ranges are much more reasonable, won the new and outdated shoppers the support and affirmation for Hot New Products Alloy C276 Flanges - Titanium Bar – Sekonic , The product will supply to all over the world, such as: Bandung, Buenos Aires, Belize, Our company will adhere to "Quality first, , perfection forever, people-oriented , technology innovation"business philosophy. Hard work to keep making progress, innovation in the industry, make every effort to first-class enterprise. We try our best to build the scientific management model, to learn abundant professional knowledge, to develop advanced production equipment and production process , to create the first-call quality products, reasonable price , high quality of service , quick delivery , to give you create new value .

This supplier's raw material quality is stable and reliable, has always been in accordance with the requirements of our company to provide the goods that quality meet our requirements.