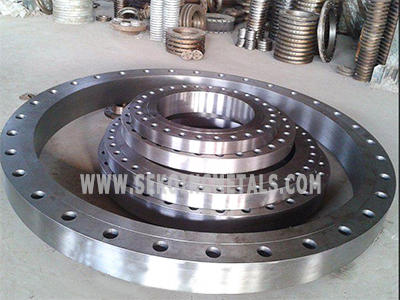

Incoloy 825 Flange

Incoloy 825 (W.Nr 2.4858) Flange

Flange Material : Incoloy Alloy 825 (UNS N08825)

Flange Types : According to clients requirments

Delivery Date : 15-30 days

Payment Term : T/T, L/C, Paypal, Ect

Sekoinc Metals Main produce and supply special alloys Flanges, we accept sample order

Alloy 825 is the The high nickel content gives the alloy effective stress corrosion cracking resistance.Corrosion resistance is good in a variety of media, such as sulfuric, phosphoric, nitric and organic acids, alkali metals such as sodium hydroxide, potassium hydroxide and hydrochloric acid solutions.

The higher overall performance of Incoloy 825 is shown in a nuclear combustion dissolver with a variety of corrosive media, such as sulfuric acid, nitric acid and sodium hydroxide, all processed in the same equipment.

| Alloy |

% |

Ni |

Cr |

Mo |

Fe |

C |

Mn |

Si |

S |

Cu |

Al |

Ti |

P |

|

825 |

Min. |

38.0 |

19.5 |

2.5 | 22.0 | - | - | - | - | 1.5 |

0.6 |

- | |

|

Max. |

46.0 |

23.5 |

3.5 | - | 0.05 | 1.0 | 0.5 | 0.03 | 3.0 | 0.2 |

1.2 |

0.03 |

|

Density

|

8.14 g/cm³

|

|

Melting point

|

1370-1400 ℃

|

|

Status

|

Tensile strength

Rm N/mm² |

Yield strength

Rp 0. 2N/mm² |

Elongation

As % |

Brinell hardness

HB

|

|

Solution treatment

|

550

|

220

|

30

|

≤200

|

• Flange Types :

→ Welding plate flange(PL) → Slip-on Neck Flange (SO)

→ Welding neck flange (WN) → Integral flange (IF)

→ Socket welding flange (SW) → Threaded flange (Th)

→ Lapped joint flange (LJF) → Blind flange (BL(s)

♦ Main Flange Materials We Produce

• Stainless Steel : ASTM A182

Grade F304 / F304L, F316/ F316L,F310, F309, F317L,F321,F904L,F347

Duplex Stainless Steel: Grade F44 / F45 / F51 / F53 / F55 / F61 / F60

• Nickel Alloys : ASTM B472, ASTM B564, ASTM B160

Monel 400, Nickel 200, Incoloy 825, Incoly 926, Inconel 601, Inconel 718

Hastelloy C276, Alloy 31, Alloy 20, Inconel 625, Inconel 600

• Titanium Alloys : Gr1 / Gr2 / Gr3 /Gr4 / GR5/ Gr7 /Gr9 /Gr11 / Gr12

♦ Standards:

ANSI B16.5 Class150、300、600、900、1500(WN,SO,BL,TH,LJ,SW)

DIN2573,2572,2631,2576,2632,2633,2543,2634,2545(PL,SO,WN,BL,TH)

Incoloy 825 Available Products in Sekonic Metals

Why Incoloy 825 ?

825 alloy is a kind of general engineering alloy, which has the acid and alkali corrosion resistance in oxidation and reduction environment and effective resistance to stress corrosion cracking for its high nickel composition.In all sorts of media, corrosion resistance is very good such as sulfuric acid, phosphoric acid, nitric acid and organic acid, to alkali, such as sodium hvdroxide, potassium hvdroxide and hvdrochloric acid solution. The higher comprehensive performance of 825 alloy shows in nuclear burning dissolver of various corrosion medium, such as sulfuric acid, nitric acid and sodium hvdroxide are all handled in the same equipment.

• Good resistance to stress corosion cracking.

• Good resistance to pitting and crevice corrosion

• Good resistance to oxidization and non oxidizing acid.

• Good mechanical properties at room temperature or up to550℃

• A certification of manufacturing pressure vessel of 450 ℃

Incoloy 825 Application field:

• Components such as heating coils, tanks, crates, baskets and chains in sulphuric acid pickling plants

• Sea-water-cooled heat exchangers, offshore product piping systems; tubes and components in sour gas service

• Heat exchangers, evaporators, scrubbers, dip pipes etc. in phosphoric acid production

• Air-cooled heat exchangers in petroleum refineries

• Food processing

• Chemical plant