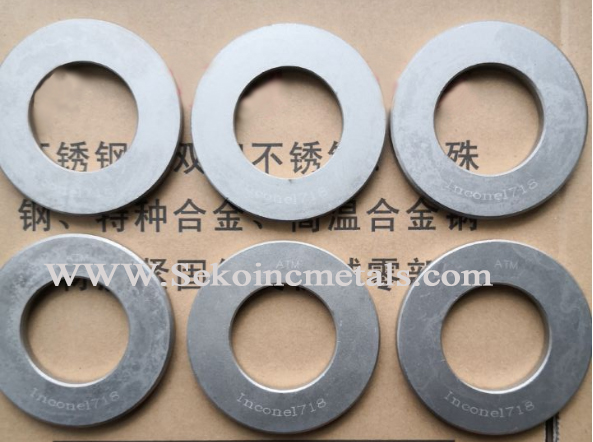

Inconel 625 Disc Ring/ Joint ring/ Washer/gasket

Inconel 625 Disc Ring/ Washer/ Gasket/ Joint Ring

♦ Material: Inconel 625(UNSNO6625)

♦ Size:M6-M36 or as per clients requirements

♦ OD 15.5-66.0mm ID:8.4-37.0mm

♦ Thickness:1.4mm-5.6mm or as per clients requiriments

♦ Application :Aero-engine parts and Aerospace structural parts

♦ Other Meaterials : Inconel 718, Inconel x750 ect

Inconel Alloy 625 is a non-magnetic, corrosion and oxidation resistant, nickel-chromium alloy. The high strength of Inconel 625 is the result of the stiffening combination of molybdenum and niobium on the nickel chromium base of the alloy. Inconel 625 has tremendous resistance to a wide range of unusually severe corrosive environments including high-temperature effects such as oxidation and carburization. Its outstanding strength and toughness in temperature ranges from cryogenic temperatures to high temperature up to 2000° F (1093° C) are derived primarily from the solid solution effects of the refractory metals Columbium and molybdenum in a nickel-chromium matrix.Common applications for this alloy are springs, seals, bellows for submerged controls, electrical cable connectors, fasteners, flexure devices, and oceanographic instrument components.

|

% |

Ni |

Cr |

Fe |

Mo |

Nb+Ta |

Co |

C |

Mn |

Si |

S |

Al |

Ti |

P |

|

Min. |

58.0 |

20.0 |

- |

8.0 |

3.15 |

- | - | - | - | - |

- |

- | - |

|

Max. |

- |

23.0 |

5.0 |

10.0 |

4.15 |

1.0 |

0.1 |

0.5 |

0.5 |

0.015 |

0.4 |

0.4 |

0.015 |

|

Density

|

8.4 g/cm³

|

|

Melting point

|

1290-1350 ℃

|

|

Status

|

Tensile strength

Rm N/mm² |

Yield strength

Rp 0. 2N/mm² |

Elongation

As % |

Brinell hardness

HB

|

|

Solution treatment

|

827

|

414

|

30

|

≤220

|

Inconel 625 Available Products in Sekonic Metals

Inconel 625 Features :

1.High creep-rupture strength

2.Oxidation resistant to 1800°F

3.Good fatigue resistance

4.Excellent weldability

5.Outstanding resistance to chloride pitting and crevice corrosion

6.Immune to chloride ion stress corrosion cracking

7.Resistant to seawater under both flowing and stagnant conditions and under fouling

Inconel 625 Application field:

• Aircraft ducting systems

• Jet engine exhaust systems

• Engine thrust-reverser systems

• Bellows and expansion joints

• Turbine shroud rings

• Flare stacks

• Seawater components

• Chemical process equipment handling mixed acids both oxidizing and reducing.