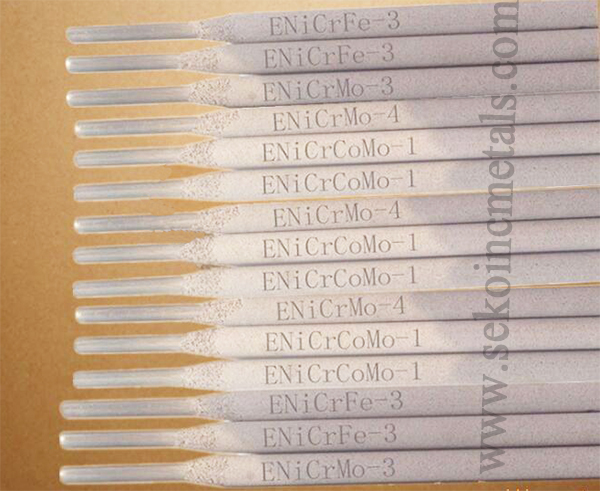

Nickel alloy/ cobalt alloy Welding Electrode

Nickel Based Alloy Welding Electrode

♦ Welding Electrode Name: ErNiCu-7 (Monel 400) , ErNiFecr-2, ErNiCrMo-3, ENicrMo-4, ErNiCr-3 Ect

♦ MOQ:30kg

♦ Size: Diameter 2.5mm-8.0mm Length:200-1000mm

♦ Standards: Conforms to Certification AWS A5.11 ASME SFA A5.11

Nickel-based electrode Application

♦♦♦ Stellite Alloy Welding Electrode ♦♦♦

• Stellite 6 (cobalt-based No. 6) electrode

The cobalt-based surfacing electrode of the cobalt-chromium-tungsten alloy core adopts DC reverse connection, and the surfacing metal can maintain good wear resistance and corrosion resistance when working at 650℃.

Application: Used in occasions where good wear resistance and corrosion resistance can be maintained when working at around 650°C, or in places subject to impact and interlocking heat and cold, such as surfacing high-temperature and high-pressure valves and hot scissors blades.

Hardfacing hardness HRC: ≥40

• Stellite 12 (Cobalt Base No. 12) electrode

Has high wear resistance, corrosion resistance and abrasion resistance. Used for high temperature and high pressure valves, cutting blades, serrations, screw push rods, etc.