OEM/ODM China Alloy Steel Flanges - Alloy 50(1J50)Permalloy – Sekonic

OEM/ODM China Alloy Steel Flanges - Alloy 50(1J50)Permalloy – Sekonic Detail:

Common Trade Names: China 1J50, Russia 50H, Hy-Ra49Permalloy

This soft magnetic alloy consisting of 49% Nickel, balance Iron used where high initial permeability. maximum permeability, and low core loss is needed

Applications:

• Electro-magnetic shielding • Specialty transformer laminations • Toroidal tape wound cores • High quality motor laminations • Stepping motors

|

Grade |

U.K. |

JANPAN |

U.S.A. |

Russia |

Standard |

|

Supermalloy (1J50) |

Mumetal |

PCS |

Hy-Ra49 |

50H |

ASTM A753-78 GBn 198-1988 |

Alloy50(1J50) Chemical Composition

| Grade |

Chemical Composition (%) |

|||||||

| C | P | S | Cu | Mn | Si | Ni | Fe | |

| Supermalloy 1J50 | ≤ | |||||||

| 0.03 | 0.020 | 0.020 | 0.20 | 0.30~0.60 | 0.15~0.30 | 49.5~50.5 | Balance | |

Alloy50(1J50) Physical Property

|

Grade |

Resistivity (μΩ•m) |

Density (g/cm3) |

Curie point °C |

saturation magnetostriction constant (×10-2) |

Tensile Strength/MPa |

Yelid Strength/MPa |

||

|

Supermalloy 1J50 |

||||||||

|

0.45 |

8.2 |

500 |

25 |

450 |

150 |

|||

Alloy50(1J50) Average Linear Expansion

|

Grade |

Coefficient of Linear Expansion at Different Temperaturel(x 10-6/K) |

||||||||

|

20~100℃ |

20~ 200℃ |

20~ 300℃ |

20~400℃ |

20~ 500℃ |

20~ 600℃ |

20~ 700℃ |

20~ 800℃ |

20~ 900℃ |

|

|

Alloy 50 1J50 |

8.9 |

9.27 |

9.2 |

9.2 |

9.4 |

– |

– | – | |

–

Mumetal Shielding Potential

Permalloy has extremely high permeability and nominal coercive force that make it a suitable material for shielding operations. To achieve the desired shielding properties, HyMu 80 is annealed up to 1900oF or 1040oC subsequent to forming processes. Annealing at the elevated temperatures enhances the permeability and shielding properties.

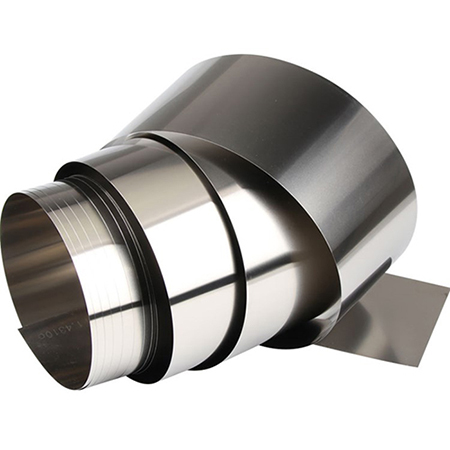

Product detail pictures:

Related Product Guide:

Special Materials we offer

Why Cobalt based Alloys

Our personnel are always in the spirit of "continuous improvement and excellence", and with the superior quality products, favorable price and good after-sales services, we try to win every customer's trust for OEM/ODM China Alloy Steel Flanges - Alloy 50(1J50)Permalloy – Sekonic , The product will supply to all over the world, such as: Curacao, Sweden, French, Only for accomplishing the good-quality product to meet customer's demand, all of our products have been strictly inspected before shipment. We always think about the question on the side of the customers, because you win, we win!

This is a honest and trustworthy company, technology and equipment are very advanced and the prodduct is very adequate, there is no worry in the suppliment.