OEM/ODM China Alloy Steel Flanges - Hiperco 50A(1J22) Bar/ Sheet/Strip/Pipe – Sekonic

OEM/ODM China Alloy Steel Flanges - Hiperco 50A(1J22) Bar/ Sheet/Strip/Pipe – Sekonic Detail:

Common Trade Names: SupermendurHiperco 50A, 1J22, Permendur, Vacoflux 50 , 50КФ

Hiperco 50A alloy is a soft magnetic alloy with 49% cobalt and 2% Vanadium,blance Iron, this alloy have the highest magnetic saturation ,which has been used primarily as magnetic core material in electrical core material in electrical equipment requiring high permeability values at very high magnetic flux densities. The magnetic characteristics of this alloy permit weight reduction, reduction of copper turns, and insulation in the end product when compared to other magnetic alloys having lower permeabilities in the same magnetic field range.

|

Grade |

U.K. |

Germany |

U.S.A. |

Russia |

Standard |

|

HiperCo50A (1J22) |

Permendur |

Vacoflux 50 |

Supermendur |

50КФ |

GB/T15002-1994 |

Hiperco50A Chemical Composition

|

Grade |

Chemical Composition (%) |

|||||||||

|

HiperCo50A 1J22 |

C≤ |

Mn≤ |

Si≤ |

P≤ |

S≤ |

Cu≤ |

Ni≤ |

Co |

V |

Fe |

|

0.04 |

0.30 |

0.30 |

0.020 |

0.020 |

0.20 |

0.50 |

49.0~51.0 |

0.80~1.80 |

Balance |

|

Hiperco50A Physical Property

|

Grade |

Resistivity /(μΩ•m) |

Density/(g/cm3) |

Curie point/°C |

Magnetostriction Cofficient/(×10-6) |

Tensile Strength,N/mm2 |

|

|

HiperCo50A 1J22 |

Unannealed |

Annealed |

||||

|

0.40 |

8.20 |

980 |

60~100 |

1325 |

490 |

|

Hiperco50A Magnetic Property

|

Type |

Magnetic Induction at different magnetic Filed strength≥(T) |

Coercivity/Hc/A/m)≦ |

|||||

|

B400 |

B500 |

B1600 |

B2400 |

B4000 |

B8000 |

||

|

Strip/Sheet |

1.6 |

1.8 |

2.0 |

2.10 |

2.15 |

2.2 |

128 |

|

Wire/Forgings |

2.05 |

2.15 |

2.2 |

144 |

|||

Hiperco 50A Production Heat Treatment

When selecting a heat treating temperature for the application, two factors should be considered:

• For best maanetic soft characteristics, select the highest suagested temperature.

• If the application requires specific mechanical properties higher than that produced when employing the highesttemperature. select the temperature that will provide desired mechanical properties.

As temperature decreases, maanetic properties become less magnetic soft. Heat treating temperature for best sofi magnetic properties should be 16259F +/-259F (885℃ +/- 15%C).Do not exceed 1652 F(900°C)The heat treating atmosphere used must be nonoxiding and noncarburizinq. Atmospheres such as dry hydrogen or high vacuum are suggested. Time at temperature should be two to four hours. Cool at a rate of nominally 180 to 360°F (100 to 200°C) per hour to a temperature of least 700 F(370C), then cool naturally to room temperature.

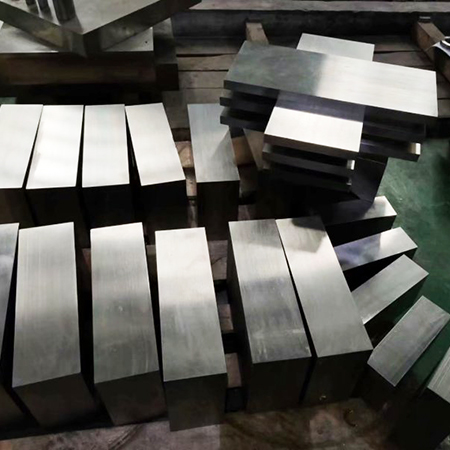

Product detail pictures:

Related Product Guide:

Why Nickel Based Alloys ?

Special Materials we offer

We are also focusing on enhancing the things administration and QC program in order that we could keep fantastic advantage within the fiercely-competitive enterprise for OEM/ODM China Alloy Steel Flanges - Hiperco 50A(1J22) Bar/ Sheet/Strip/Pipe – Sekonic , The product will supply to all over the world, such as: Cologne, New Delhi, Cyprus, Our company promises: reasonable prices, short production time and satisfactory after-sales service, we also welcome you to visit our factory at any time you want. Wish we have a pleasant and long terms business together!!!

The factory has advanced equipment, experienced staffs and good management level, so product quality had assurance, this cooperation is very relaxed and happy!