OEM/ODM China Nickel Alloy Flanges - Hastelloy B-2/B-3 Manufacture – Sekonic

OEM/ODM China Nickel Alloy Flanges - Hastelloy B-2/B-3 Manufacture – Sekonic Detail:

Common Trade Names: Hastelloy B-2,NS3202,UNS N10665,NiMo28, W.Nr.2.467,NiMo28

Hastelloy B2 is a solid solution strengthened, nickel-molybdenum alloy, with significant resistance to reducing environments like hydrogen chloride gas, and sulfuric, acetic and phosphoric acids. Molybdenum is the primary alloying element which provides significant corrosion resistance to reducing environments. This nickel steel alloy can be used in the as-welded condition because it resists the formation of grain-boundary carbide precipitates in the weld heat-affected zone. This nickel alloy provides excellent resistance to hydrochloric acid at all concentrations and temperatures. In additions, Hastelloy B2 has excellent resistance to pitting, stress corrosion cracking and to knife-line and heat-affected zone attack. Alloy B2 provides resistance to pure sulfuric acid and a number of non-oxidizing acids.

Hastelloy B-2 Chemical Composition

| C | Cr | Ni | Fe | Mo | Cu | Co | Si | Mn | P | S |

| ≤ 0.01 | 0.4 0.7 | bal | 1.6 2.0 | 26.0 30.0 | ≤ 0.5 | ≤ 1.0 | ≤ 0.08 | ≤ 1.0 | ≤ 0.02 | ≤ 0.01 |

Hastelloy B-2 Physical Properties

| Density | 9.2 g/cm³ |

| Melting point | 1330-1380 ℃ |

Hastelloy B-2 Alloy Mechanical Properties

| Condition | Tensile strength (MPa) |

Yield strength (MPa) |

Elongation % |

| Round bar | ≥750 | ≥350 | ≥40 |

| Plate | ≥750 | ≥350 | ≥40 |

| Welded pipe | ≥750 | ≥350 | ≥40 |

| Seamless tube | ≥750 | ≥310 | ≥40 |

Hastelloy B-2 Standards and Specifications

| Bar/Rod | Strip/Coil | Sheet/Plate | Pipe/Tube | Forging |

| ASTM B335,ASME SB335 | ASTM B333,ASME SB333 | ASTM B662,ASME SB662 ASTM B619,ASME SB619 ASTM B626 ,ASME SB626 |

ASTM B335,ASME SB335 | |

Hastelloy B-2 Available Products in Sekonic Metals

Hastelloy B-2 Bars & Rods

Round bars/Flat bars/Hex bars, Size From 8.0mm-320mm, Used for bolts,fastners and other spare parts

Hastelloy B2 washer & gasket

Dimension can be customized with bright surface and precision tolerance.

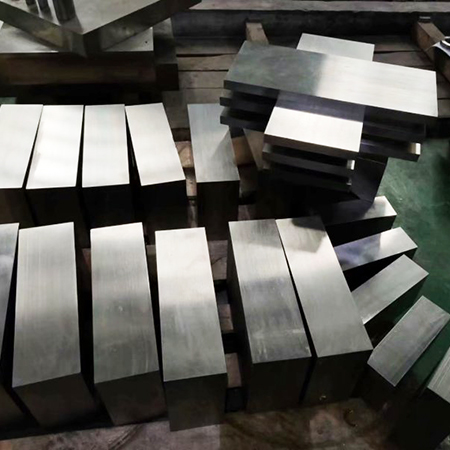

Hastelloy B-2 sheet & plate

Widths up to 1500mm and lengths up to 6000mm,Thickness from 0.1mm to 100mm.

Hastelloy B-2 seamless tube & Welded pipe

Standards size and customized dimension can be produced by us with small tolerance

Hastelloy B-2 strip & coil

Soft condition and hard condition with AB bright surface, width up to 1000mm

Hastelloy B2 fastners

Alloy B2 materials in forms of Bolts,screws,flanges and other fasterners, according to clients specification.

Why Hastelloy B-2 ?

Alloy B-2 has poor corrosion resistance to oxidizingenvironments, therefore, it is not recommended for use in oxidizing media or in the presence of ferric or cupric salts because they may cause rapid premature corrosion failure. These salts may develop when hydrochloric acid comes in contact with iron and copper. Therefore, if this alloy is used in conjunction with iron or copper piping in a system containing hydrochloric acid, the presence of these salts could cause the alloy to fail prematurely. In addition, this nickel steel alloy should not be used at temperatures between 1000° F and 1600° F because of a reduction in the ductility in the alloy.

• Excellent corrosion resistance for reductive environment.

• Excellent resistance to sulfuric acid (except for concentrated) and other non-oxidizing acids.

• Good resistance to stress corrosion cracking (SCC) caused by chlorides.

• Excellent resistance to corrosion caused by organic acids.

• Good corrosion resistance even for welding heat affect zone due to low concentration of carbon and silicon.

Hastelloy B-2 Application field:

Widely used in the chemical, petrochemical, energy manufacturing and pollution control related processing and equipment ,

especially in the processes dealing with various acids (sulfuric acid, hydrochloric acid, phosphoric acid, acetic acid

and so on

Product detail pictures:

Related Product Guide:

electropolished

Why Nickel Based Alloys ?

We have been also concentrating on enhancing the things management and QC method so that we could preserve terrific edge inside the fiercely-competitive enterprise for OEM/ODM China Nickel Alloy Flanges - Hastelloy B-2/B-3 Manufacture – Sekonic , The product will supply to all over the world, such as: Brunei, Mecca, Slovenia, We've been consistently broadening the market within Romania in addition to preparation punching in extra premium quality merchandise connected with printer on t shirt so that you can Romania. Most people firmly believe we've the whole capacity to provide you happy solutions.

In China, we have many partners, this company is the most satisfying to us, reliable quality and good credit, it is worth appreciation.