OEM/ODM Factory Alloy 718 Bar - Stellite Alloy Ring/ Shaft Sleeve – Sekonic

OEM/ODM Factory Alloy 718 Bar - Stellite Alloy Ring/ Shaft Sleeve – Sekonic Detail:

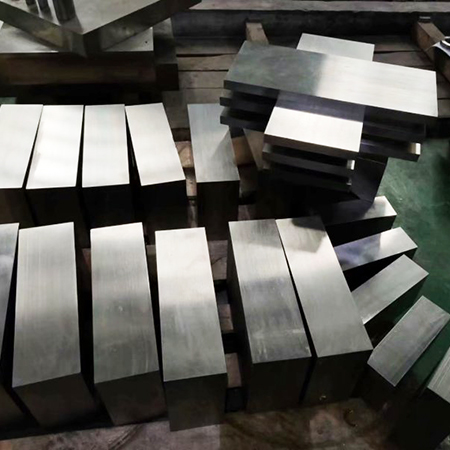

Stellite Alloy Shaft Sleeve/Ring

Material Name: Stellite 6/6B/12/25

Dimension: As Per clients specification

Delivery Date:15-45 days

Surface : Polished, Bright

Produce Method : Casting

Stellite alloys are mostly cobalt based with additions of Cr, C, W, and/or Mo. They are resistant to cavitation, corrosion, erosion, abrasion, and galling. The lower carbon allovs are generally recommended for cavitation, sliding wear, or moderate gallina. The higher carbon alloys are usually selected for abrasion, severe galling, or low- angle erosion Stellite 6 is our most popular alloy as it provides a good balance of all of these properties.

The Stellite alloys retain their properties at high temperatures where they also have excellent oxidation resistance. They are typically used in the temperature range 315-600° C (600-1112 F). They can be finished to exceptional levels of surface finish with a low coefficient of friction to give good sliding wear.

| Alloy | Composition | Hardness H.R.C | Melting range ℃ | Typical Applications |

| Stellite 6 | C: 1 Cr:27 W: 5 Co:Bal | 43 | 1280-1390 | Tough erosion-resistant alloy widely used for good all round performance. Less tendency to crack than Stellite” 12 n multiple layer, but more wear resistant than Stellite” 21 ir abrasion and metal to metal conditions. Good impact conditions. Good impact resistance. Valve seats and gates: ump shafts and bearings. erosion shields and rollina couples. Often used self-mated. Can be turned with carbide tooling. Also available as rod, electrode and wire. |

| Stellite 6B | C: 1 Cr:30 W:4.5 Co: Bal | 45 | 1280-1390 | |

| Stellite12 | C:1.8 Cr: 30 W:9 Co :Bа | 47 | 1280-1315 | Properties between those of Stellite” 1 and Stellite” 6.More abrasion resistance than Stellite” 6, but stil good impact resistance. Widely used as cutting edge in textile, timber and plastics industries and for bearinas.Also available as rod, electrode and wire. |

Stellite Alloy Available Products in Sekonic Metals

Stellite 6/6B/12 Welding Wire

Supply Stellite 6/6B/12 welding wire in coil form and cut length Form

Stellite 6B/12 Bars & Rods

Forging Round bar and casting round bar both can be produced by us as per AMS5894

Stellite 6/6B /12Ring & Sleeve

Valve seat ring, casting sleeve can be produces as clients specification

Stellite Alloy Processing :

Usually use cemented carbide tools to process 6B, and the surface accuracy is 200-300RMS. Alloy tools need to use 5° (0.9rad.) negative rake angle and 30° (0.52Rad) or 45° (0.79rad) lead angle. 6B alloy is not suitable for high-speed tapping and EDM processing is used. In order to improve the surface finish, grinding can be used to achieve high precision. Can not be quenched after dry grinding, otherwise it will affect the appearance

Stellite Alloy Application field:

Stellite can be used to manufacture valve parts, pump plungers, steam engine anti-corrosion covers, high temperature bearings, valve stems, food processing equipment, needle valves, hot extrusion molds, forming abrasives, etc.

Product detail pictures:

Related Product Guide:

Special Materials we offer

Why Nickel Based Alloys ?

"Control the standard by the details, show the power by quality". Our organization has strived to establish a highly efficient and stable employees team and explored an effective high-quality command method for OEM/ODM Factory Alloy 718 Bar - Stellite Alloy Ring/ Shaft Sleeve – Sekonic , The product will supply to all over the world, such as: Mozambique, Indonesia, Greek, Our company is continuing to serve customers with high quality, competitive price and timely delivery. We sincerely welcome friends from all over the world to cooperate with us and enlarge our business. If you are interested in our products, please feel free to contact us. We would love to provide you with further information.

The sales person is professional and responsible, warm and polite, we had a pleasant conversation and no language barriers on communication.