Inconel X-750 corrosion and oxidation resistance and high strength precipitation hardening alloy

Inconel X-750 corrosion and oxidation resistance and high strength precipitation hardening alloy,

,

Common Trade Names: Alloy X750, Nickel X750,Nicrofer 7016, Superimphy 750, Haynes X750, Pyromet X750, and Udimet X750 UNS N07750 W.NR 2.4669

Inconel® X750 is a nickel chromium alloy made precipitation hardenable by the additions of Titanium and aluminum. It has been used in high temperature structural parts such as QAS turbines, jet engine components, nuclear power plant applications, heat treatment fixtures, forming tools and extrusion dies.The alloy is highly resistant to chemical corrosion and oxidation, and has high stress endurance strength and low creep rate at high stress conditions up to 1500°F(816°C) after proper heat treatment.Inconel X-750 can be processed using traditional techniques for iron-based alloys.This alloy works hard during processing and has higher strength and “stickiness” than typical steels.Heavy machining equipment and tools should be used to reduce the flutter or work hardening of the alloy before cutting the tool.Inconel X-750 Corrosion Resistant Inconel X-750 has excellent resistance to chloride ion stress corrosion cracking.It shows satisfactory oxidation resistance in various oxidizing environments.The alloy exhibits similar corrosion resistance to alloy 600 in many media.

Inconel X750 Chemical Composition

| Alloy |

% |

Ni |

Cr |

Fe |

Nb+Ta |

Co |

C |

Mn |

Si |

S |

Cu |

Al |

Ti |

|

X750 |

Min. |

70.0 |

14.0 |

5.0 |

0.7 |

0.4 |

2.25 |

||||||

|

Max. |

- |

17.0 |

9.0 |

1.2 |

1.0 |

0.08 |

1.0 |

0.5 |

0.01 |

0.5 |

1.0 |

2.75 |

Inconel X750 Physical Properties

|

Density |

8.28 g/cm³ |

|

Melting point |

1390-1430 ℃ |

Inconel X750 Typical Mechanical Properties

| Status | Tensile strength Rm N/mm² |

Yield strength Rp 0. 2N/mm² |

Elongation As % |

Brinell hardness HB |

| Solution treatment | 1267 | 868 | 25 | ≤400 |

Inconel X750 Standards and Specifications

AMS 5667,AMS 5671,AMS 5698 ,AMS 5699 ,ASTM B637,BS HR 505,GE B14H41,ISO 15156-3 (NACE MR 0175)

| Wire | Sheet | Strip | Rod | Pipe |

| AMS5698 AMS 5699 | AMS5542 | AMS5542 | AMS 5667 AMS 5670AMS 5671 | AMS 5582 |

Inconel X750 Available Products in Sekonic Metals

Inconel X 750 Bars & Rods

Round bars/Flat bars/Hex bars, Size From 8.0mm-320mm, Used for bolts,fastners and other spare parts

Inconel X 750 welding wire

Supply in welding wire and spring wire in coil form and cut length.

Inconel X-750 Heli-Coil

Helicoil can be produced by us accepted small quantity and fast delivery.

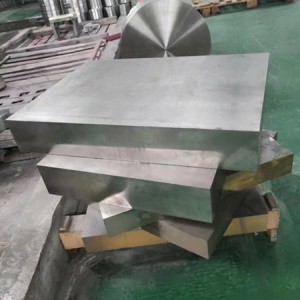

Inconel X 750 sheet & plate

Widths up to 1500mm and lengths up to 6000mm,Thickness from 0.1mm to 100mm.

Inconel X750 seamless tube & Welded pipe

Standards size and customized dimension can be produced by us with small tolerance

Inconel X 750 Spring

Spring with AMS5699 Standards according to clients drawing or specification

Inconel X750 strip & coil

Soft condition and hard condition with AB bright surface, width up to 1000mm

Inconel X 750 Fasteners

Alloy X 750 materials in forms of Bolts,screws,flanges and other fasterners, according to clients specification.

Inconel X 750 Tubing Hanger

Can be produced according to clients drawing or smaples with precision tolerance.

Inconel X-750 Features :

1.Good creep rupture strength at high temperatures

2.Not as strong as Nimonic 90

3.Very good at cryogenic temperatures

4.Age hardenable

5.High temperature dynamic applications

Inconel X-750 Application field:

• Nuclear reactors

• Gas turbines

• Rocket engines

• Pressure vessels

• Aircraft structures

Our company Products Forms

Bars & Rods

Inconel / Hastelloy/ Monel/ Haynes 25/ Titanium

Seamless Tube & Welded Tube

Nickel/ Titanium Alloy tubes, U-bend /heat exchange tube

Bolt & Nuts

Inconel 601/ Hastelloy C22/Inconel x750/Inconel 625 ect

Sheet & Plates

Hastelloy/Inconel/ Incoloy/ Cobalt/Tianium

Strip & Foil

Hastelloy/Inconel/ invar/ soft magnetic Alloys ect

High Temperature Springs

Inconel 718/Inconel x750/ Nimonic 80A

Wire & Welding

Cobalt Alloy wire, Nickel alloy wire,Tianium Alloy wire

Special Alloy Flanges

Monel 400/ Hastelloy C276/ Inconel 718/ Titanium

Oil Tube Hanger

Inconel x750/ Inconel 718 /Monel 400 ect

Nickel Based Alloys

Welding Materials

Cobalt Based Alloys

Special Stainless Steels

Precision Alloys

Titanium Alloys

Want to Learn More or get a quote ?

Get in Touch

Implementation standard :UNS, ASTM,AISI, DIN, GB/T14992, corresponding brands: GB standard brands GH4145, GH145, OCR15NI70TI3AINB, the United States label number: INCONEL X-750, NO7750, German label number:2.4669, XCR15FE7TIALInconelX – 750.

Sekonic Metals Technology Co.Committed to special alloy research and development, manufacturing, sales of X750, to ensure high quality spot supply of X750 sheet, strip, bar, forging, annular, wire and pipe., various specifications, stable supply, welcome to consult.