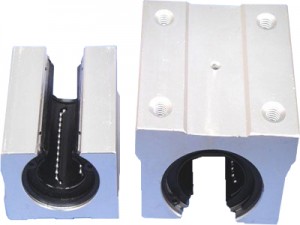

UmCO50 Slide block for step furnace

Heating furnace UMCO50 slider, CO50 heat resisting pad, CO50 slider produced according to the drawing

UMCO50 alloy produced by vacuum induction smelting, vacuum accurate casting, used for rolling plate heating furnace support block, it has good high temperature performance (1000-1300℃), good high temperature oxidation resistance and wear resistance.

Co20, Co40 and Co50 pads can effectively relieve the occurrence of laminar denudation on the top of the pad, significantly reduce the height loss of the pad and extend the effective service life of the pad, so as to improve the heating quality of the billet and significantly reduce the "black mark" temperature difference of the billet.The excellent performance of the pad comes from the more reasonable internal crystalline structure.Heating furnace CO50 slider CO50 heat resisting pad CO50 slider

Umco50 Chemical Compositions

|

C |

Cr |

Si |

Mn |

P |

S |

Fe |

Co |

|

0.05- 0.12 |

27.0- 29.0 |

0.5 -1.0 |

0.5- 1.0 |

≤0.02 |

≤0.02 |

Bal |

48.0- 52.0 |

UMCo50 Available Products in Sekonic Metals

Why UMCo50 ?

• Anti-corrosion in dilute sulfuric acid and boiling nitric acid, rapid corrosion in hydrochloric acid.

• It has stronger oxidation resistance than 25Cr-20Ni in the air to 1200°C.

• When sulfur-containing oil is used as fuel, it has high corrosion resistance in sulfur oxide environment.

• Anti-corrosion of molten copper, but rapid corrosion of molten aluminum.

UMCo50 Application field:

• Petrochemical equipment residual oil vaporization furnace forging nozzles

• High temperature and high pressure valves

• Internal combustion engine exhaust valves

• Sealing surfaces

• High temperature molds

• Steam turbine blades

• Sealing surfaces,furnace parts Wait,chain saw guide plates, plasma spray welding